Contact us

Contact details

Our offices

Unit 2, Gateway 12 Business Park, Davy Way, Gloucester, GL2 2BY, United Kingdom

Google MapsUnit 2, Gateway 12 Business Park, Davy Way, Gloucester, GL2 2BY, United Kingdom

Google Maps

Best to illustrate the structural benefits with an example: assume the lower wing skin of an aircraft.

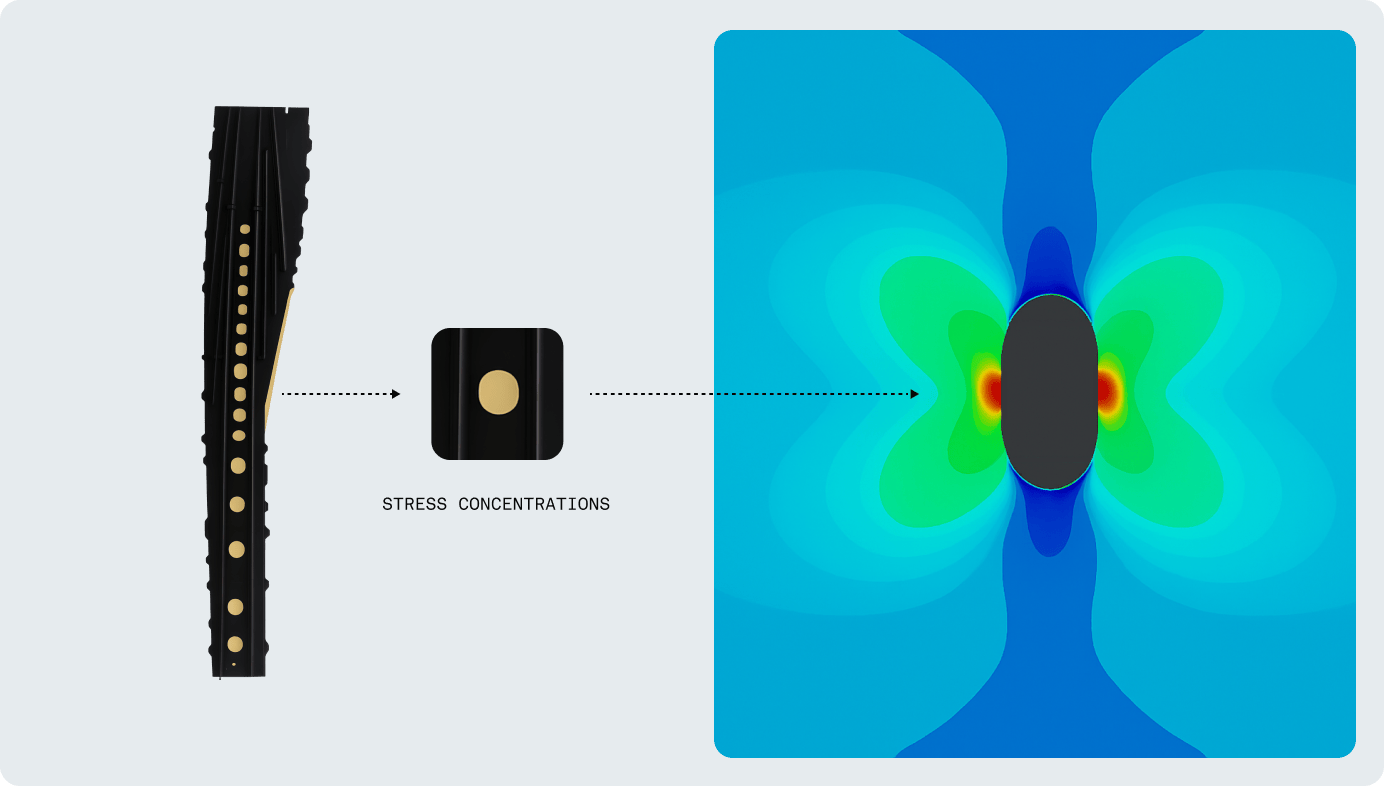

The wing is loaded in bending and ideally most of the fibers are running along its length – however the necessity for multiple large access holes, results in cut fibers and large stress concentrations. This requires significant additional material to reinforce the neighboring areas.

Representative structure (wing skin) found in defense and civil aircraft

Plot highlighting stress concentrations (red)

By steering the fibers around the holes, the stress concentrations in these areas are eliminated, leading to a drastically lighter structure, when compared to the existing straight fiber design.

This also positively impacts the production cost, as significantly less carbon layers are needed (less raw material, less layup time).

RTS tapes deposited around a hole

Laminate | Load (kN) | Mass (kg) | Tsai-Wu failure criterion | Load / Mass (kN/kg) |

|---|---|---|---|---|

| Quasi-isotropic (24 plies) | 358 | 3.71 | 1.001 | 96.5 |

| RTS (8 plies) | 358 | 1.30 | 0.8969 | 275 |

RTS delivers up to 65% weight reduction compared to conventional laminates — same strength, one-third the material.

The optimal fiber orientation, at every layer, at every point of a structure. This is the power of RTS. Because with fiber steering the design space is drastically expanded, and a lighter/stronger result will always be achieved vs straight fiber.

ICOMAT - RTS

65% reduced weight

Fiber Steering is key to unlock manufacturing of complex composite parts at industrial production rates. The best way to achieve this is a forming/stamping workflow (high rate / low cost / automated workflow, validated in automotive).

However, unlike metals which stretch in all directions, carbon fiber and composites cannot stretch in the fiber direction. This has been the main bottleneck for stamping/forming of complex composite parts. Fiber Steering adds an additional degree of freedom, enabling to pre-steer the fibers in a 2D preform, which can then be stamped without forming defects.

Forming Analysis

2D Preform Production

Stamping or Forming

Complex 3D Parts Optimized Fiber Paths